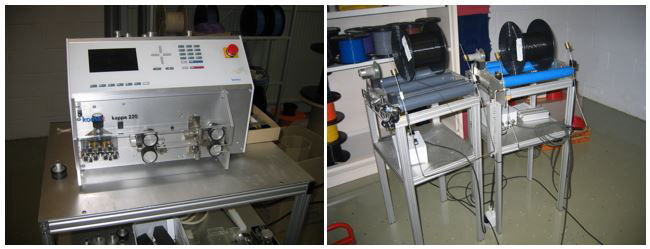

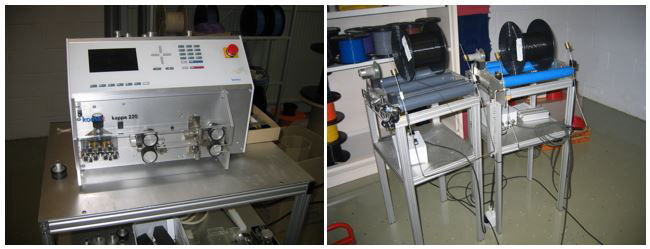

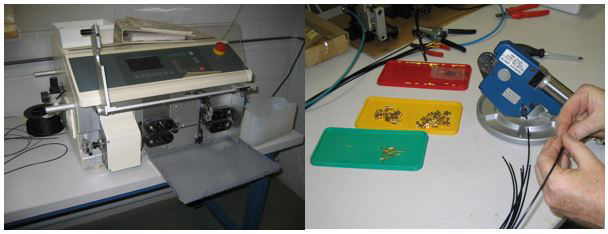

Cabelectron can supply cable assemblies to your exact specifications when you need them.

Whether you want custom cable assemblies specifically designed, or a cable assembly manufactured from

your specification, Cabelectron has the capability. See below for some of our manufacturing capabilities.